SPT Vilecon Case Study

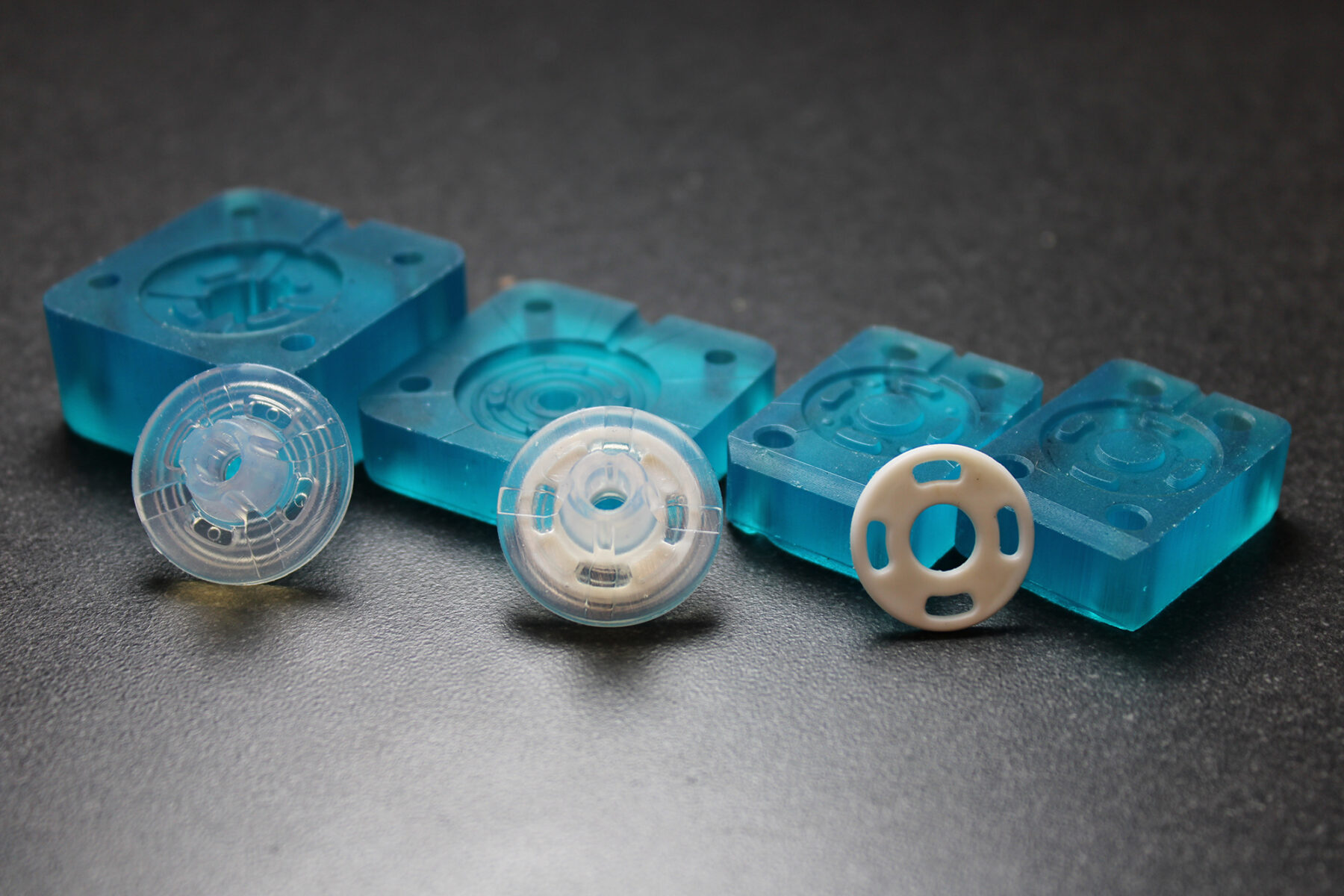

With Freeform Injection Molding and XiP Desktop 3D Printer, SPT Vilecon was able to offer a customer developing an intravenous silicone product, early design and material verification by utilization of 3D printed tools.

View Case Study